Normal Temperature Water-cooled refrigerated air dryer for air compressor

- Model

- SLAD-80NW

Item specifics

- Air inlet temperature

- ≤45°C

- Cooling way

- Water-cooled

- Cooling Water Inlet Temp

- ≤32°C

- Pressure dew point

- 2~10°C

- Air inlet pressure

- 0.6~1.0MPa

- Pressure loss

- ≤3% of inlet pressure

- Place of origin

- Hangzhou, China

- Certification

- CE CCC ISO9001

- Color

- Customized

- Warranty

- 1 year

Review

Description

Product name: Water-cooled refrigerated air dryer

Product model: SLAD-80NW

Technical Specifications

● Capacity:0.5-300m3/min

● Max working pressure:1.6 MPa

● Max.inlet temperature: 60 C

● Max.Ambient temperature: 50 C

● Min.ambient temperature: 5 C

● Cooling type: air-cooled

● Power supply: 220V/380V/50Hz or 60Hz

● Refrigerant: R134a /R407C /R410A

*Rated condition:

● Working pressure 0.7MPa,

● Inlet temperature 38C

● Ambient temperature 38C

● PDP 2-10C

● OEM and ODM service is available.

● Compressor:Hitachi or Bitzer

● Hot gas by pass valve:Danfoss

● Automatic expansion valve:Danfoss

● Heat Exchanger:Aluminum plate fin type

● Auto Drain:Electric Drainer

● Note: Refrigerator air dryer without metal box board for over 80 m3/ min.

● Other special standards can be customized.

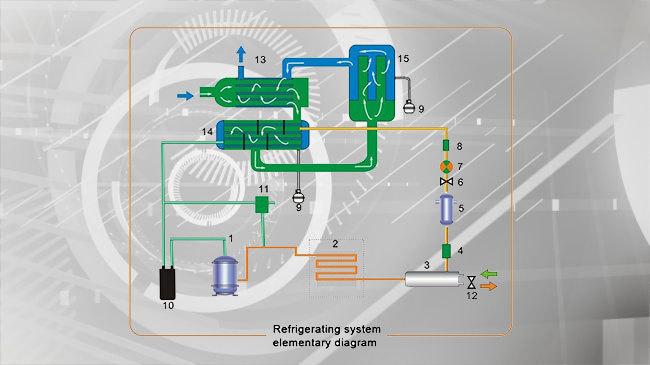

Working Principle

Refrigeration compressed air dryer makes the water vapor in the compressed air condenses into droplets through cooling so as to achieve the purpose of reducing moisture content. Condensed droplets are discharged by the automatic drainage system.

1.Air dryer gas liquid separator uses a three-stage separation: direct collision separation high speed centrifugal

separation stainless steel wire mesh demister separator.

2.Domestic evaporator welding is basically using copper pipe welding, distribution pipe and collecting pipe

welding contact surface is small, poor welding strength and easily lead to false welding. We use the domestic

latest pull whole process, a great increase in the copper welding surface. It resolves the evaporator leakage

problem in present market basically.

3.The new designed air dryer uses stainless steel triple plate or alloy aluminum plate to replace the traditional

carbon steel material, avoid the secondary pollution problems from carbon steel corrosion and reduce the risk of

leakage. Greatly enhance the product performance, reduce the size of equipment, but also bring visual aesthetics

to the customer.

Annotation:

| 1. Cooling medium compressor | 6. Manual valve | 11. Hot gas by-pass valve |

|---|---|---|

| 2. Air condenser | 7. Cooling medium sight glass | 12. Water volume adjustable valve |

| 3. Water condenser | 8. Expansion valve | 13. Pre-cooling gas |

| 4. Magnetic valve | 9. Automatic drainer | 14. Evaporator |

| 5. Drying filter | 10. Gas water separator | 15. Effective separator |

Performance Parameters

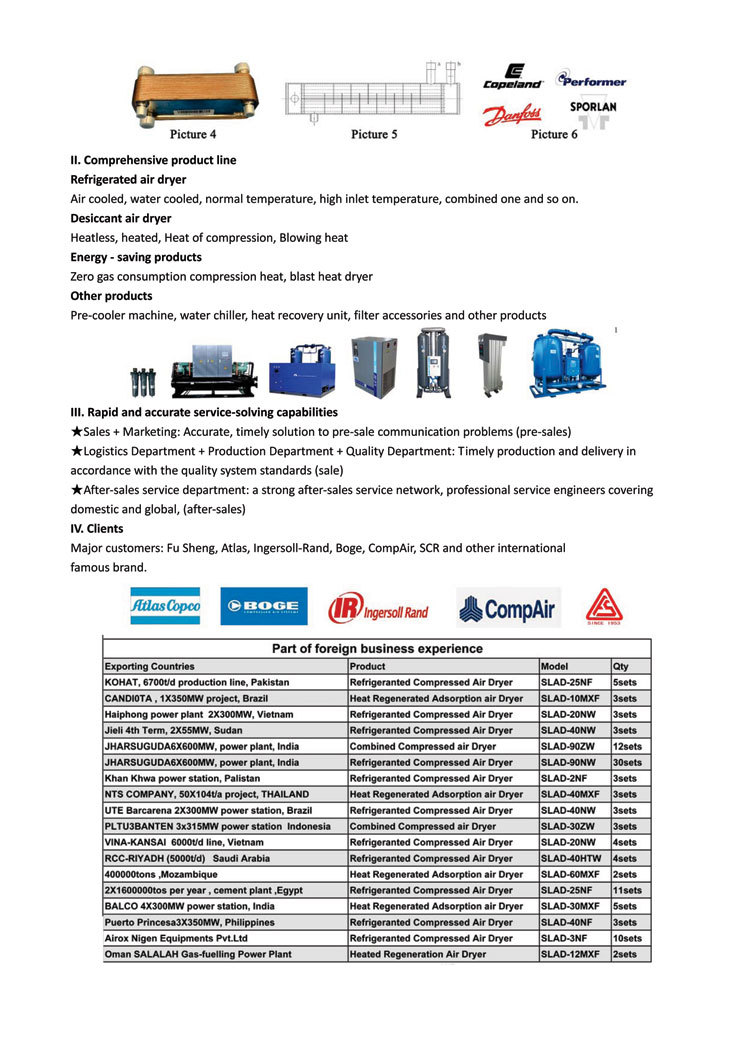

| Refrigerated Compressed Air Dryer | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Model | Flow Capacity (Nm3/min) | Voltage (V) | Fan Power (W) | Pipe Diameter | Air Inlet Pressure (Mpa) | Net Weight (Kg) | Length (mm) | Width (mm) | Height (mm) | Air Flow (N3/h) |

| SLAD-0.5NF | 0.65 | 220 | 1x67 | G1/2" | 0.6-1.0 MPa | 45 | 750 | 430 | 610 | 760 |

| SLAD-1NF | 1.2 | 220 | 1x67 | G1" | 70 | 780 | 450 | 610 | 760 | |

| SLAD-2NF | 2.5 | 220 | 1x95 | G1" | 110 | 800 | 460 | 720 | 1580 | |

| SLAD-3NF | 3.6 | 220 | 1x150 | G1" | 130 | 950 | 480 | 720 | 3150 | |

| SLAD-4.5NF | 5 | 220 | 1x240 | G1 1/2" | 150 | 1170 | 540 | 750 | 5580 | |

| SLAD-6NF | 6.8 | 220 | 2x150 | G1 1/2" | 160 | 1350 | 520 | 753 | 6300 | |

| SLAD-8NF | 8.5 | 220 | 2x195 | G2" | 200 | 1100 | 670 | 1098 | 8470 | |

| SLAD-10NF | 10.9 | 380 | 2x195 | G2" | 250 | 1200 | 670 | 1098 | 8470 | |

| SLAD-12NF | 12.8 | 380 | 2x195 | G2" | 300 | 1200 | 670 | 1048 | 8470 | |

| SLAD-15NF | 16 | 380 | 2x190 | DN65 | 320 | 1460 | 750 | 1630 | 8470 | |

| SLAD-20NF | 22 | 380 | 2x240 | DN65 | 420 | 1670 | 800 | 1663 | 11160 | |

| SLAD-25NF | 26.8 | 380 | 2x240 | DN80 | 550 | 1820 | 800 | 1713 | 11160 | |

| SLAD-30NF | 32 | 380 | 2x380 | DN80 | 650 | 1900 | 860 | 1875 | 15240 | |

| SLAD-40NF | 43.5 | 380 | 3x240 | DN100 | 2200 | 2200 | 930 | 1941 | 16740 | |

| SLAD-50NF | 53 | 380 | 3x380 | DN100 | 2450 | 2450 | 900 | 2110 | 22860 | |

| SLAD-60NF | 67 | 380 | 4x380 | DN125 | 2140 | 2140 | 1450 | 1787 | 30480 | |

| SLAD-80NF | 90 | 380 | 4x550 | DN125 | 2070 | 2070 | 1600 | 2029 | 42400 |

Package and Shipment

● Packing details: Wooden crate pallet plus foam board and bubble film, Full closed wooden case. 1pcs/each package (for stationary desiccant air dryer)

● Transportations: sea transport, rail transport, air transport, road transport, LCL/ FCL container transport or as requested

● Trade terms: FOB, CFR, CIF and EXW, DDP, etc.

● Delivery time: in 20 days after receiving deposit (customized machines not included)

Company Information

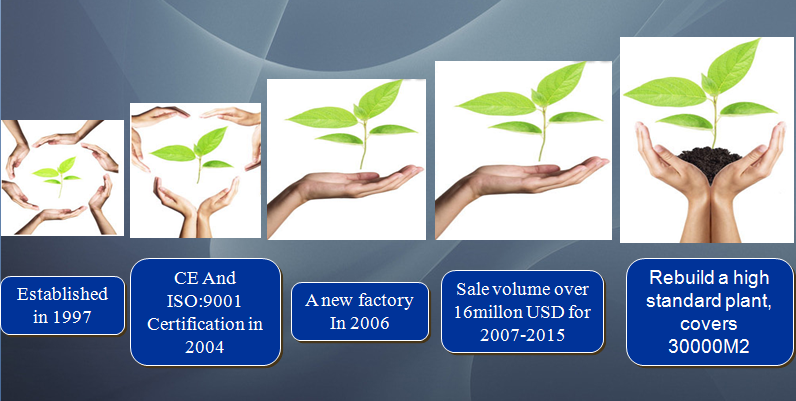

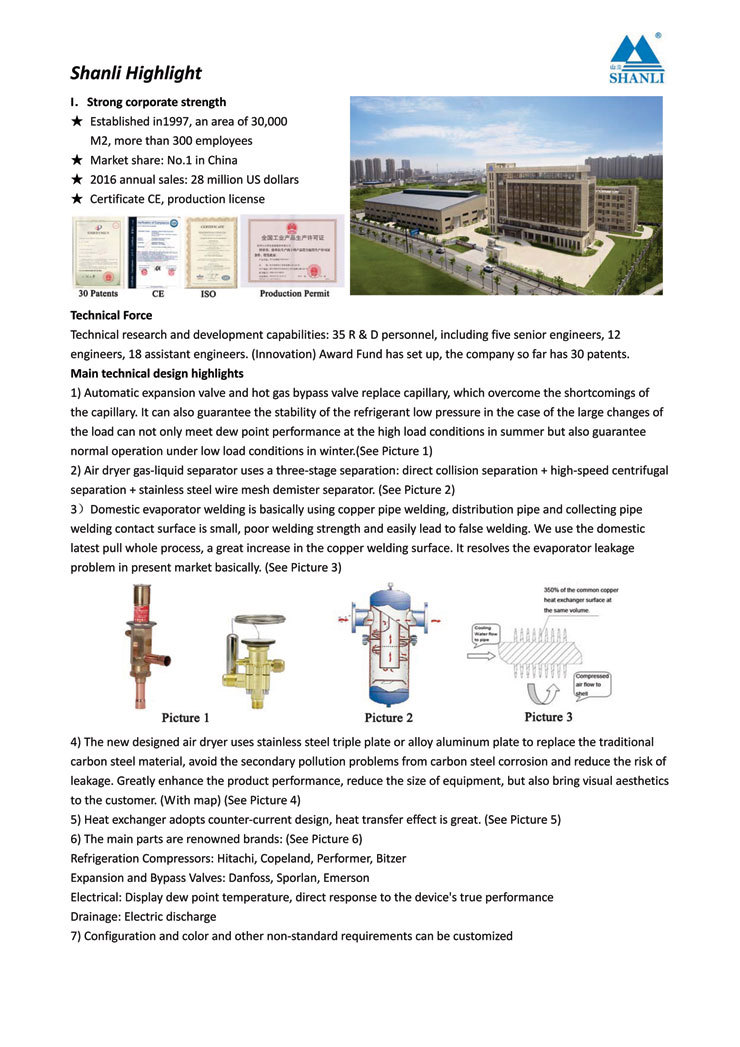

● Established in 1997, Hangzhou Shanli Purify Equipment Corporation is an enterprise specialized in design, development

and production of compressed air dryers, filters and other purification equipments. Our company has a workshop of

30, 000 square meters and more than 300 staff. Shanli has become one of the largest refrigerated air dryer manufacturers

in the Chinese purification industry with the top sales turnover. Our self-design and self-made equipment is compatible with many

famous brands of air compressor to efficiently remove water, oil and dustfrom compressed air. On basis of IS0 9001

certification standard, our design, production, test and services of the machine are all well managed and strictly

controlled since year 2001.

Advantage

1. Quality:

● Certification: CE, ISO-9001, ISO-14001 and 26 patents to ensure unmatched quality of our product assortment.

● Stringent quality control mechanism: updating the involved technology as per prevailing international standards;

● Stable performance: using premium grade raw material from highly reputed manufacturers, like Danfoss, Emerson, Performer, Bitzer, Fusheng, Sprolan;

2. Customer:

● Some of major cooperated customers (from our wide range of customers ) have been enlisted below for reference:

| S.NO. | VALUED CUSTOMERS | S.NO. | VALUED CUSTOMERS | S.NO. | VALUED CUSTOMERS |

|---|---|---|---|---|---|

| 1 | Atlas Copco | 2 | BOGE Kompressoren | 3 | Ingersoll Rand |

| 4 | CompAir Air Compressors | 5 | Sinopec Group | 6 | Sullair Asia |

3. Scale:

● Shanli has become one of largest manufacturers in purifying industry of China with annual sales turnover USD 22 million.

● Shanli has a wide range of customers who have full faith in our service delivery, warranty, quality and workmanship.

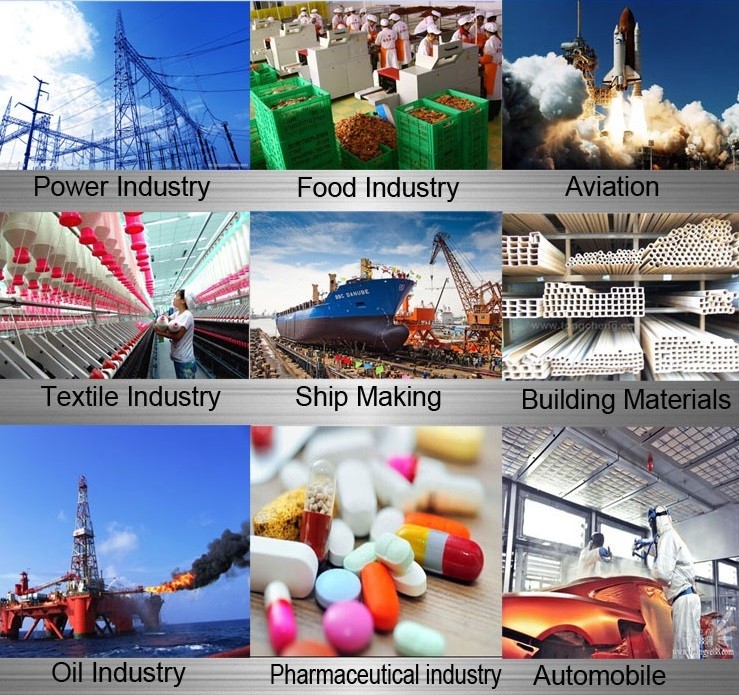

Product Applications

There are still some areas and applications where Shanli air dryers can be used, such as power construction, packing food, making ship, cleaning medical molding,removing EDM recast and discoloration, finishing and texturing injection mold cavities, cleaning orifices in turbine blades, engraving optical lenses,cleaning and preparation of semi-precious stones and jewelry, etc.

Why to chose Shanli?

Comprehensive Product Line

Refrigerated Air Dryer

Air cooled/Water cooled Type, Normal inlet temperature type(60℃)/High inlet temperature type(80℃)

Desiccant Air Dryer

Heatless/Heated Type, Heat of Compression, Blower Purge Type

Energy ‐ saving Products

Heat of Compression Type(Zero Purge)/Blower Purge Type(Zero Purge),Combined type air dryer

Other Products

Pre‐cooler machine, Water chiller, Heat recovery unit, Filter accessories and other products

Contacts

Hangzhou Shanli

Add: No.8,Liangzhan Road, Renhe Street,Hangzhou, 311107, China

Tel:86-571-86392999

Fax:86-571-86392998