Waste Heat Recovery system with Plate Heat Exchanger

- Model

- SRPS-22ZR-O-N

Item specifics

- Air compressor Power

- 22 KW

- Recovery efficiency

- 16 KW

- Water inlet and outlet temp

- 5 ℃ of normal water & 60 ℃ of heated water

- Max hot water output

- 244 kg/h

- Oil tube diameter

- DN25

- Water tube diameter

- DN25

- Size

- Customized by different compressors

- Reduced CO2 emission

- 48 ton per year

- Saved electric cost

- 12,700 USD

- Warranty

- 1 year

Review

Description

Shanli air dryer detail information

Product name: Heat Recovery System

Product model: SRPS-22ZR-O-N

Introduction

● Heat recovery is a method of salvaging a portion of the energywasted by inefficient Heating, Venting, and Air Conditioning (HVAC) systems.

● HVAC systems have a limited efficiencydue to the laws of thermodynamics and inherent inefficiencieswith real applications.

● Energy that would be used for work isinstead dissipated in the form of heat.

● Heat recovery units(HRUs) harness some of this energy and redirect it for a morepractical use.

● HRUs are typically found in applications thatrequire both heating and cooling.

Technical Features

● Built into air compressor , customized and integrally formed;

● Precise control of the oil temperature between 82-88;

● Air outlet temperature below 50;

● Lubricant consumption save 20%;

● compactand easy to maintain;

● Avoid pipeline Oil leaking;

● Economicaland cost-effective.

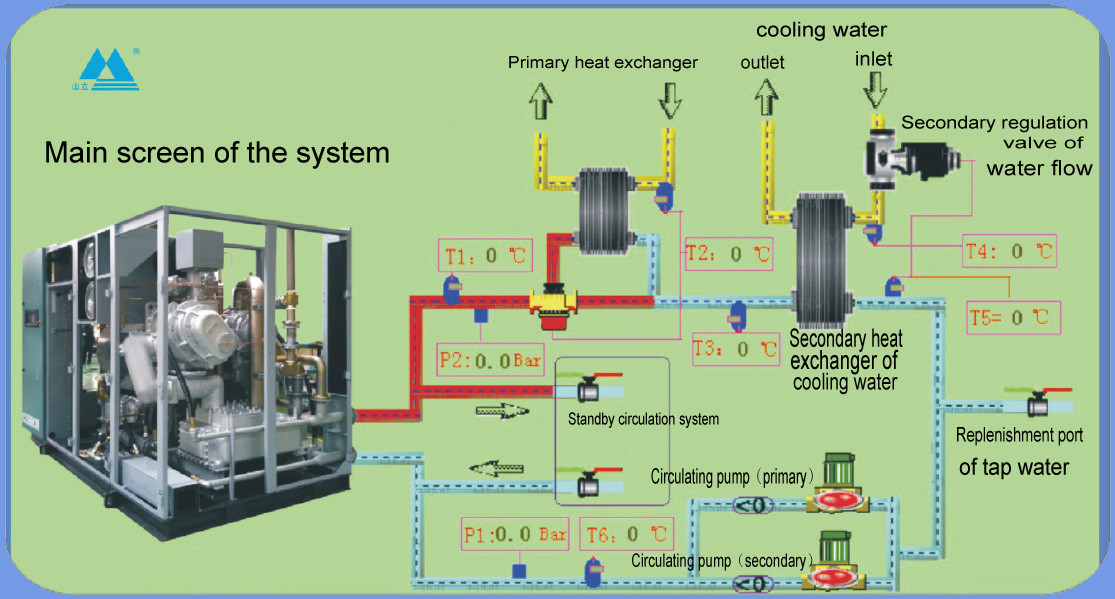

Working Principle

● Thesystem can be applied to recycle most of refrigerator heat in an oil-free andwater-cool air compressor.

● This recyclable part of refrigerator heat accountsfor 80%-95% of input shaft power.

● If a MD air dryer is installed in the rear ofthe compressor, the recovery rate falls by approximately 9%-25%, the energy ofwhich is restored for the regeneration during drying process.

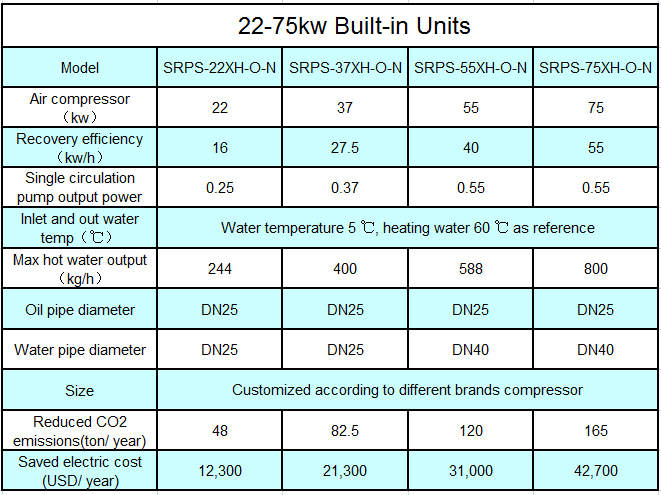

Performance Parameters

Package and Shipment

● Packing details: Wooden crate pallet plus foam board and bubble film, Full closed wooden case. 1pcs/each package (for stationary desiccant air dryer)

● Transportations: sea transport, rail transport, air transport, road transport, LCL/ FCL container transport or as requested

● Trade terms: FOB, CFR, CIF and EXW, DDP, etc.

● Delivery time: in 20 days after receiving deposit (customized machines not included)

Company Information

● Hangzhou Shanli Purify Equipment Corp., was formed in 1997, as a compressed air solutions company.

● The workshop at integrated engineers and contractors has a dedicated team, which is continuously engaged in upbringing of new technologies for greater efficiency.

● The company was involved in supplying of refrigerated air dryers, desiccant air dryers, compressed air filters, oil water separators and water chillers as a manufacturer, exporter and supplier.

Advantage

1.Technical Force

Technical research and development capabilities: 35 R & D personnel, including five senior engineers, 12

engineers, 18 assistant engineers. (Innovation) Award Fund has set up, the company so far has 30 patents.

2.Strong Corporate Strength

Established in1997, an area of 30,000M2, more than 300 employees

Market share: No.1 in China

2016 annual sales: 28 million US dollars

Certificate ISO/ CE, production license

3.Automatic expansion valve and hot gas bypass valve replace capillary, which overcome the shortcomings of

the capillary. It can also guarantee the stability of the refrigerant low pressure in the case of the large changes of

the load can not only meet dew point performance at the high load conditions in summer but also guarantee

normal operation under low load conditions in winter.

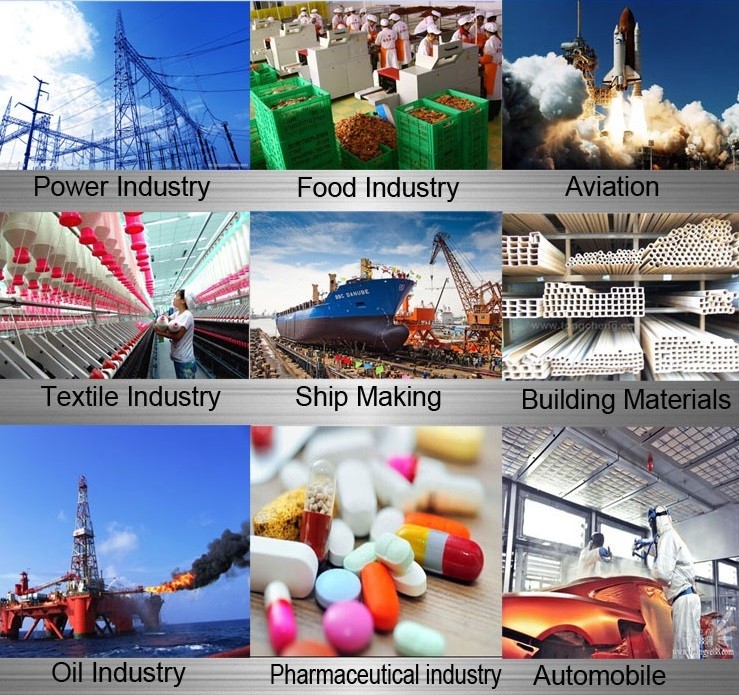

Product Applications

There are still some areas and applications where Shanli air dryers can be used, such as power construction, packing food, making ship, cleaning medical molding,removing EDM recast and discoloration, finishing and texturing injection mold cavities, cleaning orifices in turbine blades, engraving optical lenses,cleaning and preparation of semi-precious stones and jewelry, etc.

Contacts

Hangzhou Shanli

Add: No.8,Liangzhan Road, Renhe Street,Hangzhou, 311107, China

Tel:86-571-86392999

Fax:86-571-86392998

Email: jovelyzou@hzsljh.com