factory use Combined Compressed Air Dryer for air compressor

- Model

- SDZW-8

Item specifics

- Air inlet temp

- 20-60°C

- Oil Content

- <=0.1PPM

- Air consumption

- 3-5%

- Pressure dew point

- -40°C (standard type)

- Air inlet pressure

- 0.6~1.6MPa

- Pressure loss

- 3-5% of inlet pressure

- Place of origin

- Hangzhou, China

- Certification

- CE CCC ISO9001

- Power

- AC 380V-50HZ/ AC220V-50HZ

- Cycling time

- T=40 min

Review

Description

Combined Compressed Air Dryer for Japan

Introduction

● Combined low dew point air dryer is the equipment which combines refrigerated air dryer and adsorption air dryer.

● Using a new process, low consumption, high energy saving and intelligent operation to meet the different needs of users.

Main Features

1.Sturdy and durable Different from Carbon steel material product.Using 304S stainless steel for heat exchanger, water

separator and air connections can avoid the secondary pollution to air quality, so the SSD series dryer can be directly

used for food ,medicine, semiconductor, senior spraying field and etc.

2.Nano anticorrosive coating on air condenser makes the useful life longer.

3.Energy saving and environmental protection

4.Heat exchanger is following Europe and America advanced plate-fin structure, highly heat-efficiency;

Technical Specifications

● Pressure range: 0.6-1.6 Mpa

● Max air inlet temp.: 60 Deg C

● Max ambient temp.: 50 Deg C

● Max cooling water inlet temp.: 38 Deg C

● Cooling method: air-cooled type/water-cooled type

● Power: 380V/220V/1PH/50HZ

● Refrigerant: R-22, R407C, R-134A

● Max pressure loss: 5% of air inlet pressure

● Control method: PLC control

● Pressure dew point: -40 Dec C

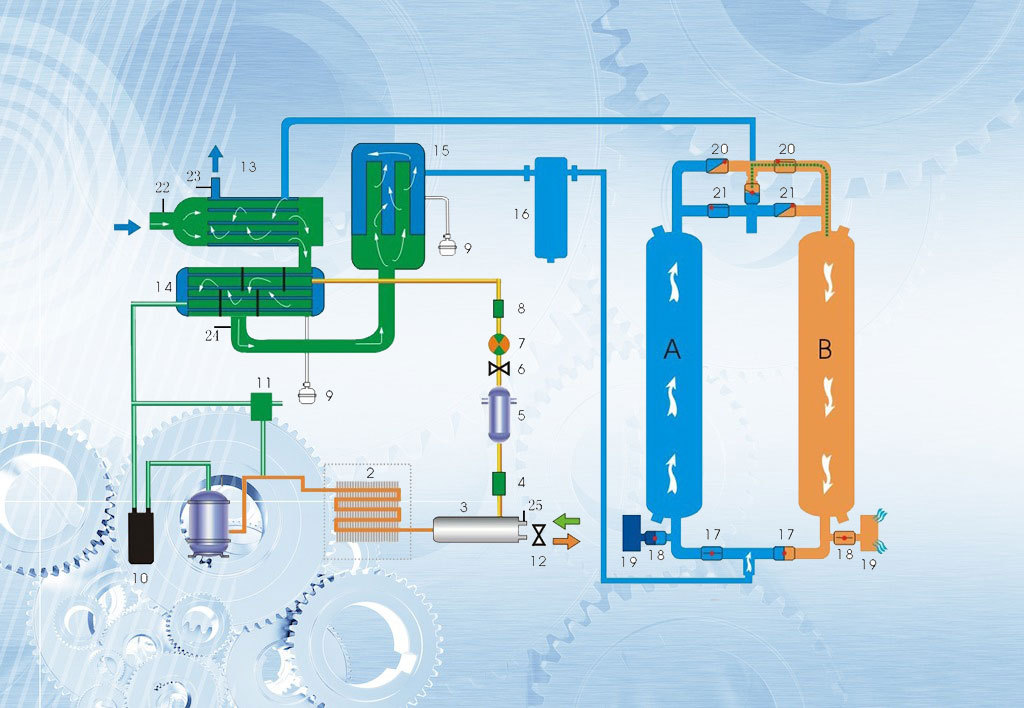

Working Principle

● Refrigerated air dryers has a strong water remove capability.

● While desiccant air dryer can reach a lower dew point -40℃.

● The air consumption is only 1/5 of the normal desiccant air dryer.

● The prominent advantages are energy saving and high quality low dew point air.

1. cooling medium compressor | 2. air condenser | 3. water condenser | 4. magnetic valve |

|---|---|---|---|

5. drying filter | 6. manual valve | 7. cooling medium sight glass | 8. expansion valve |

9. automatic drain | 10. water glass separator | 11. hot gas by-pass valve | 12. water volume adjustable valve |

13. pre-cooler | 14. evaporator | 15. effective separator | 16. oil-free filter |

17. air inlet valve | 18. air drain valve | 19. silencer | 20. regenerative one-way valve |

21. air outlet one-way valve | A. adsorptive tower | B. adsorptive tower |

Model Parameters

| Model | Air Flow Capacity | Air Pipe | Cooling Water Pipe | Cooling Power | Desiccant weight /two tower | Weight | Length | Width | Height | |

|---|---|---|---|---|---|---|---|---|---|---|

| (Nm3/min) | cfm | (HP) | (kg) | (kg) | (mm) | (mm) | (mm) | |||

| SDZW-6 | 6.8 | 240.3 | G1 1/2" | R1" | 1.5 | 112 | 760 | 1500 | 1160 | 1940 |

| SDZW-8 | 8.5 | 300.4 | G2" | R1" | 2 | 156 | 960 | 1500 | 1100 | 2116 |

| SDZW-10 | 10.9 | 385.2 | G2" | R1" | 2.5 | 197 | 1120 | 1500 | 1240 | 2316 |

| SDZW-12 | 12.8 | 452.3 | G2" | R1" | 2.5 | 220 | 1190 | 1500 | 1240 | 2316 |

| SDZW-15 | 16 | 565.4 | DN65 | R1 1/2" | 3 | 273 | 1660 | 1800 | 1450 | 2192 |

| SDZW-20 | 22 | 777.4 | DN65 | R1 1/2" | 4 | 395 | 1740 | 1970 | 1610 | 2470 |

| SDZW-25 | 26.8 | 946.9 | DN80 | R1 1/2" | 5 | 491 | 2075 | 2030 | 1630 | 2505 |

| SDZW-30 | 32 | 1130.7 | DN80 | R1 1/2" | 6 | 600 | 2200 | 2240 | 1840 | 2519 |

| SDZW-40 | 43.5 | 1537.1 | DN100 | R1 1/2" | 7 | 722 | 2848 | 2360 | 1900 | 2637 |

| SDZW-50 | 53 | 1872.8 | DN100 | R1 1/2" | 10 | 862 | 3144 | 2600 | 2000 | 2638 |

| SDZW-60 | 67 | 2367.5 | DN125 | R1 1/2" | 12 | 1030 | 3361 | 2540 | 2100 | 2719 |

| SDZW-80 | 90 | 3180.2 | DN125 | R1 1/2" | 13.3 | 1333 | 4500 | 2640 | 2500 | 2818 |

| SDZW-100 | 110 | 3887 | DN150 | R2" | 20 | 1940 | 6550 | 2960 | 2670 | 2985 |

| SDZW-120 | 130 | 4582 | DN150 | R2" | 25 | 2370 | 7810 | 3070 | 2800 | 3041 |

| SDZW-150 | 160 | 5639 | DN200 | R2 1/2" | 25 | 2785 | 8500 | 3600 | 3130 | 3190 |

| SDZW-200 | 210 | 7402 | DN200 | R2 1/2" | 40 | 3374 | 9600 | 3700 | 3450 | 3311 |

| SDZW-250 | 260 | 9164 | DN250 | R3" | 60 | 4580 | 12100 | 4230 | 4110 | 3569 |

| SDZW-300 | 315 | 11102 | DN250 | R3" | 70 | 5354 | 12800 | 4700 | 4210 | 3730 |

Package and Shipment

● Packing details: Wooden crate pallet plus foam board and bubble film, Full closed wooden case. 1pcs/each package (for stationary desiccant air dryer)

● Transportations: sea transport, rail transport, air transport, road transport, LCL/ FCL container transport or as requested

● Trade terms: FOB, CFR, CIF and EXW, DDP, etc.

● Delivery time: in 20 days after receiving deposit (customized machines not included)

Company Information

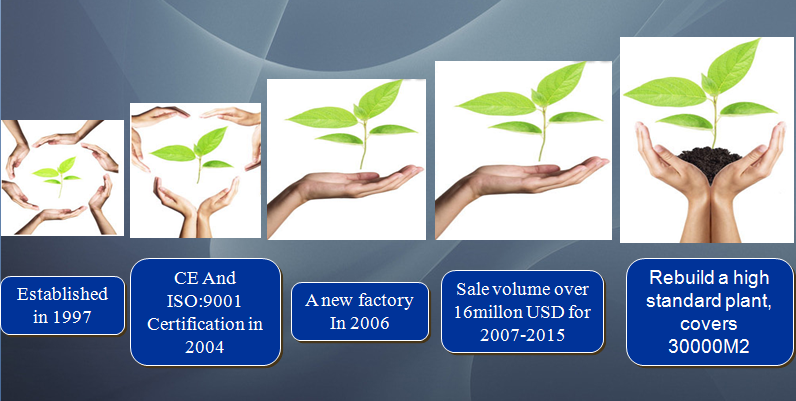

● Established in 1997, Hangzhou Shanli Purify Equipment Corporation is an enterprise specialized in design, development

and production of compressed air dryers, filters and other purification equipments. Our company has a workshop of

30, 000 square meters and more than 300 staff. Shanli has become one of the largest refrigerated air dryer manufacturers

in the Chinese purification industry with the top sales turnover. Our self-design and self-made equipment is compatible with many

famous brands of air compressor to efficiently remove water, oil and dustfrom compressed air. On basis of IS0 9001

certification standard, our design, production, test and services of the machine are all well managed and strictly

controlled since year 2001.

Advantage

1. Quality:

● 1.Rapid and Accurate Service-solving Capabilities

●2.Sales Marketing: Accurate, timely solution to pre sale communication problems (pre sales)

●3.Logistics Department Production Department Quality Department: Timely production and delivery in

accordance with the quality system standards (sale)

●4.After sales service department: a strong after sales service network, professional service engineers covering

domestic and global, (after sales)

2. Customer:

● Some of major cooperated customers (from our wide range of customers ) have been enlisted below for reference:

| S.NO. | VALUED CUSTOMERS | S.NO. | VALUED CUSTOMERS | S.NO. | VALUED CUSTOMERS |

|---|---|---|---|---|---|

| 1 | Atlas Copco | 2 | BOGE Kompressoren | 3 | Ingersoll Rand |

| 4 | CompAir Air Compressors | 5 | Sinopec Group | 6 | Sullair Asia |

3. Scale:

● Shanli has become one of largest manufacturers in purifying industry of China with annual sales turnover USD 22 million.

● Shanli has a wide range of customers who have full faith in our service delivery, warranty, quality and workmanship.

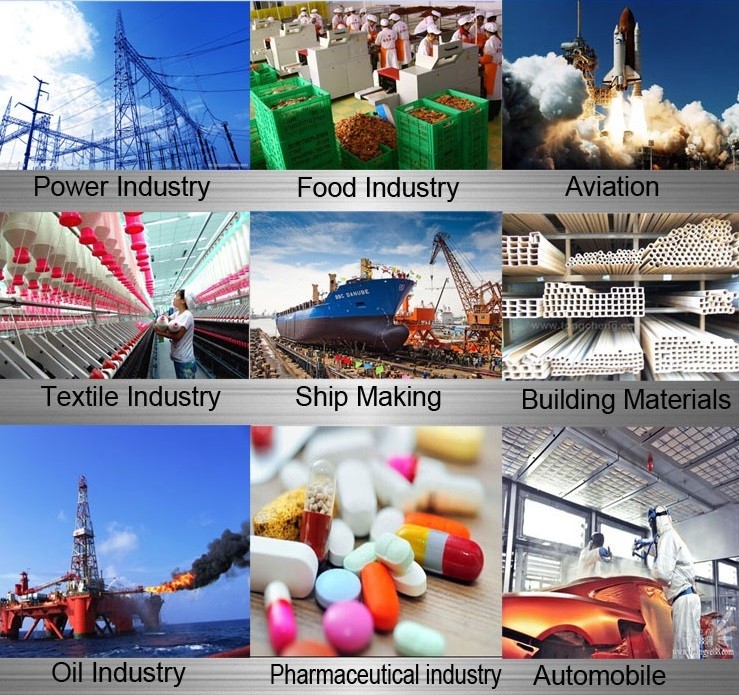

Product Applications

Shanli refrigerated air dryers are widely used in industry such as Metallurgy industry,machinery industry,chemical fiber,light industry,

paper making,rubber making,instrument making, Biomedical Industry and daily chemical industry.

Contacts

Hangzhou Shanli

Add: No.8,Liangzhan Road, Renhe Street,Hangzhou, 311107, China

Tel:86-571-86392999

Fax:86-571-86392998

Email: jovelyzou@hzsljh.com

Website: www.slairdryer.com