Hot Saling active alumina heated adsorption air dryer

- Model

- SLAD-15MXF

Item specifics

- Air inlet temp

- 20-45°C

- Oil Content

- <=0.1PPM

- Air consumption

- <=7%

- Pressure dew point

- -40°C

- Air inlet pressure

- 0.6~1.0MPa

- Pressure loss

- ≤3% of inlet pressure

- Place of origin

- Hangzhou, China

- Certification

- CE CCC ISO9001

- Power

- AC 380V-50HZ/ AC220V-50HZ

- Warranty

- 1 year

Review

Description

Information

● Regenerative desiccant dryers use desiccant media to dry compressed air through the process of adsorption.

● Dry air with dew points of either -20°C, -30°C, or -40°C can be achieved.

● These extremely low dew points are necessary in critical compressed air applications or for those in extremely cold environments

● In such environments, any moisture remaining in the air would freeze inside compressed air system piping, resulting in blocked flow.

Technical Specifications

● Max air inlet temp.: 45 Deg C

● Max air inlet pressure.:0.6-1.0 Mpa

● Air consumption: <=7% of inlet air

● Pressure loss; <=3% of inlet pressure

● Oil content: <=0.1PPM

● Pressure dew point: -40 Deg C (standard type)

● Control method: PLC control

● Power: AC 380V/220V-50HZ

● Cycling time: T=2 h

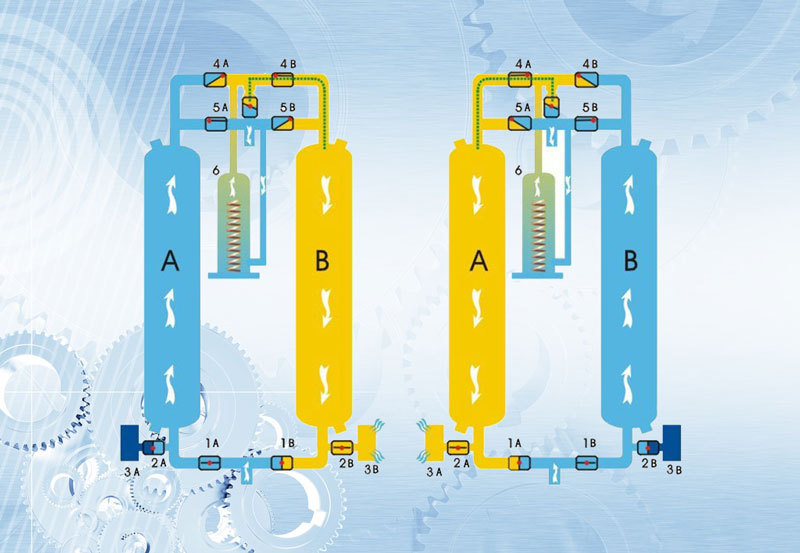

Working Principle

● During dryer operation, the desiccant media is used to dry the air followed by a period of regeneration when the media is purged of the moisture it collects so it can be used again for drying.

● Twin-tower design of our dryers allows simultaneous air drying and desiccant regeneration-without interruption of compressed air flow.

Note:

| 1. Gas inlet valve | 2. Gas drain valve | 3. Silencer |

|---|---|---|

| 4. Regenerative one-way valve | 3. Gas outlet one-way valve | A.B. Adsorptive tower |

Performance Parameters

| Heated Regeneration Adsorption Air Dryer | ||||||||

|---|---|---|---|---|---|---|---|---|

| Model | Air Capacity | Desiccant Weight (Kg) | Air Pipe Diameter | Net Weight (Kg) | Length (mm) | Width (mm) | Height (mm) | |

| (Nm3/min) | cfm | |||||||

| SLAD-1MXF | 1.2 | 42 | 24 | G1" | 186 | 812 | 620 | 1417 |

| SLAD-2MXF | 2.5 | 88 | 40 | G1" | 256 | 732 | 586 | 2017 |

| SLAD-3MXF | 3.6 | 127 | 60 | G1" | 341 | 962 | 638 | 1711 |

| SLAD-4.5MXF | 4.8 | 169 | 85 | G1 1/2" | 447 | 842 | 642 | 2225 |

| SLAD-6MXF | 6.8 | 240 | 120 | G1 1/2" | 630 | 950 | 642 | 2105 |

| SLAD-8MXF | 8.5 | 300 | 158 | G2" | 678 | 1288 | 696 | 2231 |

| SLAD-10MXF | 10.9 | 384 | 190 | G2" | 810 | 1288 | 696 | 2331 |

| SLAD-12MXF | 12.8 | 451 | 190 | G2" | 810 | 1288 | 696 | 2331 |

| SLAD-15MXF | 16 | 564 | 310 | DN65 | 983 | 1743 | 735 | 2356 |

| SLAD-20MXF | 22 | 775 | 492 | DN65 | 1271 | 1933 | 736 | 2415 |

| SLAD-25MXF | 26.8 | 945 | 578 | DN80 | 1371 | 1903 | 823 | 2738 |

| SLAD-30MXF | 32 | 1128 | 600 | DN80 | 1550 | 2101 | 913 | 2462 |

| SLAD-40MXF | 43.5 | 1533 | 856 | DN100 | 1994 | 2200 | 1002 | 2576 |

| SLAD-50MXF | 53 | 1868 | 1002 | DN100 | 2127 | 2213 | 1002 | 2594 |

| SLAD-60MXF | 67 | 2361 | 1718 | DN125 | 3243 | 2716 | 1270 | 2857 |

| SLAD-80MXF | 90 | 3172 | 2300 | DN125 | 3698 | 2816 | 1453 | 2911 |

| SLAD-100MXF | 110 | 3877 | 2800 | DN150 | 4677 | 3312 | 1751 | 3094 |

| SLAD-120MXF | 130 | 4582 | 3370 | DN150 | 5140 | 3420 | 1900 | 3159 |

| SLAD-150MXF | 160 | 5639 | 4070 | DN200 | 6126 | 3812 | 1900 | 3378 |

| SLAD-200MXF | 210 | 7402 | 5530 | DN200 | 8370 | 4224 | 2235 | 3534 |

| SLAD-250MXF | 260 | 9164 | 6116 | DN250 | 13100 | 4616 | 2647 | 3805 |

| SLAD-300MXF | 310 | 10926 | 7016 | DN250 | 15000 | 4816 | 2802 | 3883 |

Package and Shipment

● Packing details: Wooden crate pallet plus foam board and bubble film, Full closed wooden case. 1pcs/each package (for stationary desiccant air dryer)

● Transportations: sea transport, rail transport, air transport, road transport, LCL/ FCL container transport or as requested

● Trade terms: FOB, CFR, CIF and EXW, DDP, etc.

● Delivery time: in 20 days after receiving deposit (customized machines not included)

Company Information

● Hangzhou Shanli Purify Equipment Corp., was formed in 1997, as a compressed air solutions company.

● The workshop at integrated engineers and contractors has a dedicated team, which is continuously engaged in upbringing of new technologies for greater efficiency.

● The company was involved in supplying of refrigerated air dryers, desiccant air dryers, compressed air filters, oil water separators and water chillers as a manufacturer, exporter and supplier.

Advantage

1. Quality:

● Certification: CE, ISO-9001, ISO-14001 and 26 patents to ensure unmatched quality of our product assortment.

● Stringent quality control mechanism: updating the involved technology as per prevailing international standards;

● Stable performance: using premium grade raw material from highly reputed manufacturers, like Danfoss, Emerson, Performer, Bitzer, Fusheng, Sprolan;

2. Customer:

● Some of major cooperated customers (from our wide range of customers ) have been enlisted below for reference:

| S.NO. | VALUED CUSTOMERS | S.NO. | VALUED CUSTOMERS | S.NO. | VALUED CUSTOMERS |

|---|---|---|---|---|---|

| 1 | Atlas Copco | 2 | BOGE Kompressoren | 3 | Ingersoll Rand |

| 4 | CompAir Air Compressors | 5 | Sinopec Group | 6 | Sullair Asia |

3. Scale:

● Shanli has become one of largest manufacturers in purifying industry of China with annual sales turnover USD 22 million.

● Shanli has a wide range of customers who have full faith in our service delivery, warranty, quality and workmanship.

Contacts

Hangzhou Shanli

Add: No.8,Liangzhan Road, Renhe Street,Hangzhou, 311107, China

Tel:86-571-86392999

Fax:86-571-86392998

Email:jovelyzou@hzsljh.com

website: www.slairdryer.com