2019 newest 7bar modular desiccant compressed air dryer

- Model

- SDCM-6J

Item specifics

- Air inlet temp

- <=35 °C

- Air inlet pressure

- 0.7 Mpa

- Air consumption

- <=1.5 %

- Pressure loss

- 0.15 bar(g)

- Dew point

- -40 °C

- Inlet oil content

- <=0.01 PPM

- Place of origin

- Hangzhou, China

- Certification

- CE CCC ISO9001

- Power

- AC 380V-50HZ/ AC220V-50HZ

- Warranty

- 1 year

Review

Description

Shanli air dryer detail information

Product name: Modular Desiccant Air Dryer

Product model: SDCM-6J

Introduction

● The SDXM series is a lightweight modular desiccant dryer that offers unsurpassed installation flexibility.

● This lightweight modular dryer design brings a whole new concept in compressed air technology offering total installation flexibility to meet your specific needs.

● A small amount of the dried compressed air is used to regenerate the saturated desiccant bed by expanding air from line pressure to atmospheric pressure, removing the moisture absorbed by the desiccant material.

● Protection is built-in. Extruded aluminum housings that surround the dryers are fully protected from corrosion.

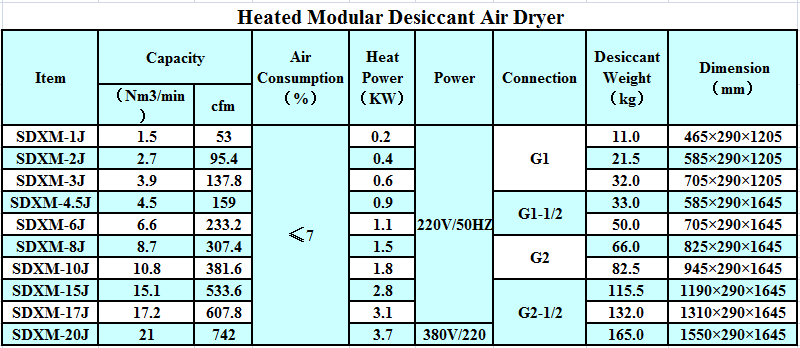

Technical Specifications

● Maximum operating temperature: 95 °F (35 °C)

● Maximum working presure: 145 psig (10 bar)

● Air capacity: 53 to 742 cfm (1.5 to 21 m3/min)

● Maximum air consumption: 1.5 % of inlet air

● Maximum pressure loss: 2.175 psig (0.15 bar)

● Pressure dew point: -40 °F (-40 °C)

● Maximum inlet oil content: 0.01 PPM

Features

● High-efficiency filtration and dessicant bed absorption provides clean, dry air;

● Compact, fully integrated unit is installed at point-of-use, so you pay for drying only the air needed;

● Conservative pressure drop lowers power costs;

● Prevents corrosion and minimizes production disruptions;

● For use with compressors with aftercoolers.

Performance Parameters

Package and Shipment

● Packing details: Wooden crate pallet plus foam board and bubble film, Full closed wooden case. 1pcs/each package (for stationary desiccant air dryer)

● Transportations: sea transport, rail transport, air transport, road transport, LCL/ FCL container transport or as requested

● Trade terms: FOB, CFR, CIF and EXW, DDP, etc.

● Delivery time: in 20 days after receiving deposit (customized machines not included)

Company Information

●Established in 1997 with a new workshop covers 30, 000 M2

●CE and ISO 9001:2008 certification

●Annual output of 12,000 sets of equipment

●The most 31 patents among the industry

●Export to 100 different countries

●Sales voume in 2016 with 30 million USD

●OEM service for Boge and supporting supplier for Atlas,Compair,Ingersoll Rand

Advantage

1. Quality:

● Certification: CE, ISO-9001, ISO-14001 and 26 patents to ensure unmatched quality of our product assortment.

● Stringent quality control mechanism: updating the involved technology as per prevailing international standards;

● Stable performance: using premium grade raw material from highly reputed manufacturers, like Danfoss, Emerson, Performer, Bitzer, Fusheng, Sprolan;

2. Customer:

● Some of major cooperated customers (from our wide range of customers ) have been enlisted below for reference:

| S.NO. | VALUED CUSTOMERS | S.NO. | VALUED CUSTOMERS | S.NO. | VALUED CUSTOMERS |

|---|---|---|---|---|---|

| 1 | Atlas Copco | 2 | BOGE Kompressoren | 3 | Ingersoll Rand |

| 4 | CompAir Air Compressors | 5 | Sinopec Group | 6 | Sullair Asia |

3. Scale:

● Shanli has become one of largest manufacturers in purifying industry of China with annual sales turnover USD 22 million.

● Shanli has a wide range of customers who have full faith in our service delivery, warranty, quality and workmanship.

Product Applications

There are still some areas and applications where Shanli air dryers can be used, such as power construction, packing food, making ship, cleaning medical molding,removing EDM recast and discoloration, finishing and texturing injection mold cavities, cleaning orifices in turbine blades, engraving optical lenses,cleaning and preparation of semi-precious stones and jewelry, etc.